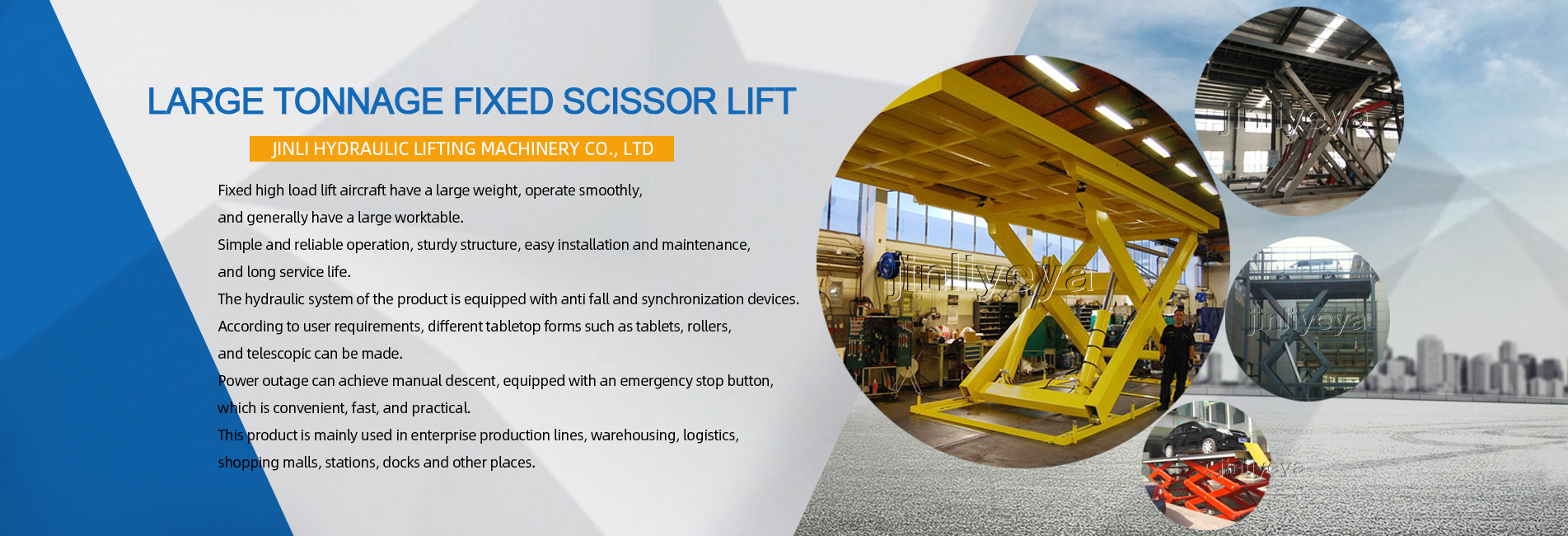

structural characteristics

- rigid chain This is a key component of the rigid chain lifting platform, which is connected by multiple rigid chain links through hinges. During the lifting process, the chain can withstand significant axial pressure and achieve stable lifting actions.

- driving deviceUsually, a motor is used to drive the sprocket, which rotates when the motor is running, thereby driving the rigid chain to rise or fall. Some products are also equipped with reducers to adjust the speed and torque, ensuring a smooth and uniform lifting process.

- guide mechanismTo ensure that the platform does not tilt or shake during the lifting process, guide devices such as rails and guide wheels are installed. The guide rails are generally installed on both sides of the platform, and the guide wheels cooperate with the guide rails to guide the platform vertically up and down along a fixed trajectory.

- platform structure Used to carry goods or personnel, the size and carrying capacity of the platform vary according to usage needs. The surface is usually treated with anti slip measures, and safety protection devices such as guardrails are also installed around it.

working principle

When the driving motor receives the control signal and starts running, it reduces the speed and increases the torque through the reducer, driving the sprocket to rotate. The sprocket meshes with the rigid chain, and as the sprocket rotates, the rigid chain rises or falls vertically under the constraint of the guiding mechanism, thereby driving the platform connected to it to achieve lifting and lowering actions. During the lifting process, the control system will monitor the position, speed, and chain force of the platform in real time. When the set lifting or lowering position is reached, the motor s running and the platform s at the corresponding height. In addition, there are multiple safety protection mechanisms, such as limit switches (to prevent the platform from exceeding the limit position), overload protection devices (to automatically stop when the load exceeds the rated value), etc., to ensure the safe operation of the equipment.

Application scenarios

- industrial manufacturingIn the factory workshop, it is used for the handling of goods between different floors, such as transporting parts from the ground floor to processing equipment at high places, or transporting finished products from high places to the ground for packaging and transportation, to improve production efficiency.

- logistics warehousingIt can realize the transfer of goods between shelves of different heights in a three-dimensional warehouse, especially suitable for vertical transportation of heavy goods. With the help of an automated logistics system, it can achieve automated operation of goods storage and sorting.

- automotive industryOn the automobile production line, it is used for the distribution of automobile parts and the lifting inspection of the entire vehicle, facilitating workers to install, debug, and inspect parts such as the vehicle chassis.

- commercial premisesIn some commercial buildings such as shopping malls and supermarkets, it is used for transporting goods on different floors, such as transporting large goods from underground warehouses to business floors, to meet the logistics needs of commercial operations.

advantage

- Strong carrying capacityRigid chains can withstand greater pressure. Compared to some flexible rope lifting equipment, rigid chain lifting platforms have higher load-bearing capacity and can meet the lifting needs of heavy goods. Common load-bearing capacities range from several hundred kilograms to several tons.

- Good stabilityThe combination of guiding mechanism and rigid chain enables the platform to maintain good stability during the lifting process, avoiding tilting or shaking, ensuring the safety of goods and personnel.

- High securityEquipped with various safety protection devices, in addition to the limit switches and overload protection mentioned above, there may also be anti fall devices, chain breakage protection, etc., which greatly improves the safety of equipment operation.

- Compact sizeIts structure is relatively compact, especially in the vertical direction where it occupies less space, making it more suitable for places with limited space.

limitation

- Limited lifting speedDue to the limitations of the rigid chain structure and drive system, compared to some high-speed elevators and other lifting equipment, the lifting speed of the rigid chain lifting platform is relatively slow, which is not suitable for situations that require high lifting speed.

- High installation and maintenance requirementsThe installation process requires adjusting the position and accuracy of components such as chains and guide rails to ensure the normal operation of the equipment. In terms of maintenance, it is necessary to regularly check the wear of the chain, the meshing status of the sprocket, and the lubrication of the guide mechanism, making maintenance work relatively complex.